+86-18005412752

- Language:中文EnglishРусский языкEspaña한국어

News

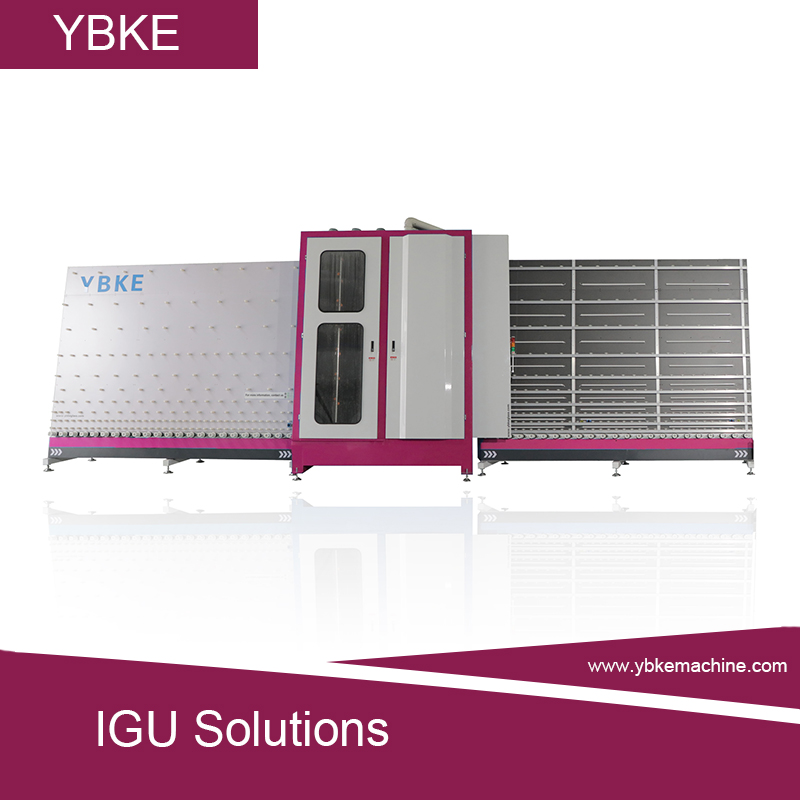

As they have developed, glass manufacturing industries have focused on not only producing standard glass but insulated glass. One specific reason for insulated glass production is the increasing demand for it in areas with harsh weather conditions. Furthermore, it is the perfect solution to prevent heat loss because insulated glass is essentially constructed of trapped air between two glass panes. Insulated glass comprises two or more sheets of glass spaced apart with a spacer bar and tightly sealed with a primary and secondary sealant to form a single unit. Insulated glass machines are designed for the specific purpose of producing these insulated glass units.

What is an Insulated Glass Machine?

Machines specifically designed to produce insulated glass are known as insulating glass machines. Glass cutting, glass edging, glass washing and drying, spacer assembly, pressing, sealing, and gas filling are some of the main manufacturing steps for insulated glass. Insulating glass equipmentprimarily consists of the following components:

Vertical insulating glass production line: In the production line, this machine is one of the main elements as it is responsible for producing insulated glass units by combining two glass panes while keeping a distance between them.

Glass cutting and edging equipment: This machine is responsible for accurate and efficient cutting and polishing the edge of the glass after it is insulated.

Glass washing and drying equipment: This commercial washing and cleaning machine is designed to swiftly and effectively rinse many glass panes.

Butyl Extruder Machine: The basic sealing of spacer bars of various thicknesses for insulated glass units is made using a butyl extruder.

Two-component sealant extruding equipment: To allow for the second sealing of IG units, the two-component sealant extruder employs silicone or bi-component polysulphide.

● Gas filling equipment: The gas filling equipment is used to fill the insulated glass with a gas (usually inert gas).

Applications of Insulated Glass Machine

The glass produced by the insulated glass machines has an unending list of applications, such as:、

Insulated glass is used to improve a building's ability to use energy. The amount of electricity needed to heat or cool the area is reduced because of the reduced heat transfer. This significantly lowers the cost of electricity, especially in regions with harsh temperatures.

It is used for insulation as it lowers heat gain and heat loss. Adding additional glass layers with gas infill substantially insulates the building and its windows from heat loss.

Insulated glass aids in sound absorption and enhances the environment's acoustics. The inert gas sandwiched between the two panes of glass prevents noise from passing through and serves as a buffer between the building's interior and the noise outside.

If you are interested in our product, please feel free to call us+86 18005412752

Copyright ©Copyright:Jinan YBKE Machinery Co., Ltd Recordatio:ICP备********号 Website Map(Baidu / Google)

Technical Support:YBKE[Hollow glass equipment] YBKE