+86-18005412752

- Language:中文EnglishРусский языкEspaña한국어

News

Insulating glass was invented by the Americans in 1865. It is a good new building material with the characteristics of heat insulation and sound insulation. With the development of the domestic glass processing industry and people's continuous in-depth understanding of the advantages and pe…

How to choose a cost-effective insulating glass gluing machine? First of all, it depends on the size of the company. Large-scale companies have more mature technology and stable equipment performance, so as to ensure timely after-sales service in the future, stable technical personnel, and a so…

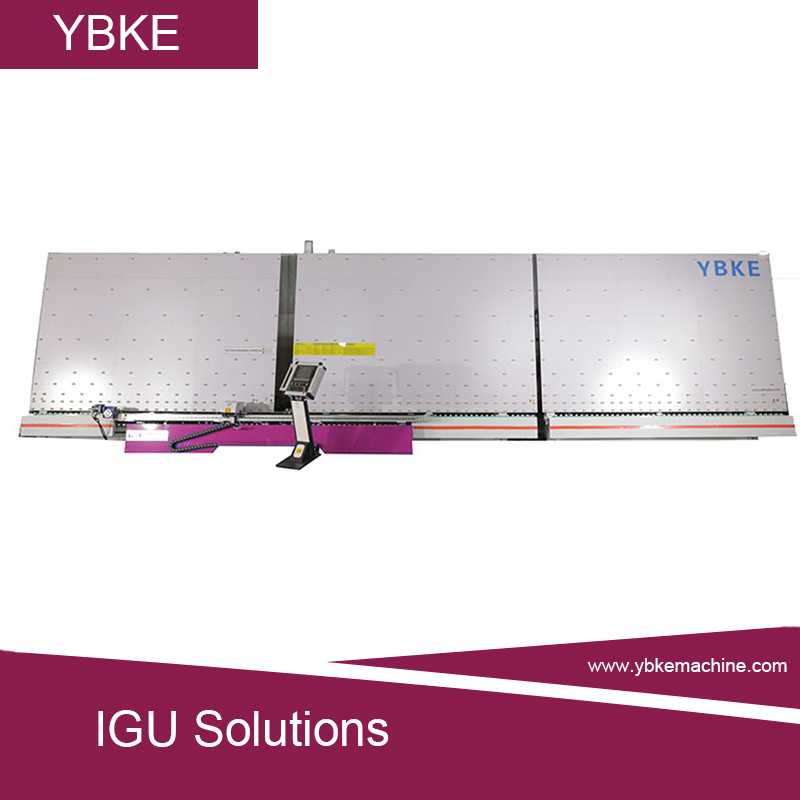

The insulating glass production line is divided into 1600 insulating glass production line, 1800 insulating glass production line, 2000 insulating glass production line, 2200 insulating glass production line and 12500 insulating glass production line according to the size of the processed glass…

Insulating glass processing has changed from manually applying insulating glass sealant, to using a manual two-component gluing machine to apply glue with a gun, to a horizontal automatic gluing machine, and now to a fully automated insulating glass gluing machine.

The company has set up plastic steel door and window equipment manufacturing plant, broken bridge aluminum door and window equipment and insulating glass production line manufacturing plant. With better products, better service and more reasonable price, our customers are more satisfied.

Copyright ©Copyright:Jinan YBKE Machinery Co., Ltd Recordatio:ICP备********号 Website Map(Baidu / Google)

Technical Support:YBKE[Hollow glass equipment] YBKE